Due to continuous evolution in the technology sector the cost and size of devices has decreased to a great extent.The systems are becoming more smart and responsive.Artificial intelligence is at its pedestal and is said to produce more advanced and responsive systems in future.The tracking system is on its phase of shifting from the days of QR/UPC(Universal Product Code) codes to a new advanced system i.e RFID which stands for Radio Frequency Identification.

The QR code i.e the Quick Response Code is the data which is machine readable and is a form of a barcode.The barcodes are read-only data that means that the data in the barcode can’t be modified later.The QR code is an advanced form of the barcode which can contain more than 3800 alphanumeric characters with the constraint of limited space.The QR codes are widely used for multipurpose aims-

- Used for the billing of products at the billing counter.

- Used for tracking the status of a product in the inventory system.

- Used for searching an object or tracking its location.

- Used to uniquely identify an item.

That was about QR codes.The systems have significantly advanced to the extent that the data can be modified also.This introduces the RFID(Radio Frequency Identification).

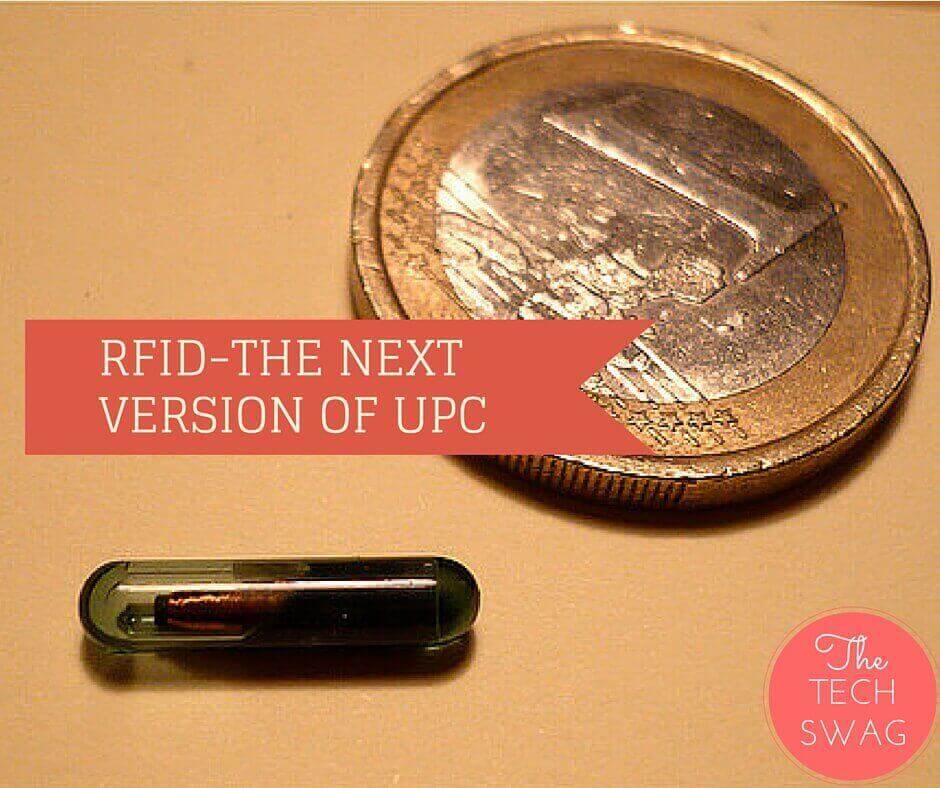

The RFID uses wireless electromagnetic fields to automatically track and identify the tags attached to the systems and objects.These tags are very small in size, smaller than the size of a coin(As you can see in the first picture).The two essential components in RFID is the tag and the reader.The tag mainly stores the information while the reader is used to track/grasp the information from the tag.

The biggest advantage of the RFID is that it is not necessary for the tag to be in the line of sight, unlike the barcode/QR code which are needed to be clearly visible to read.The tag in RFID may be embedded inside the tracked object.The reader will automatically track the tag when it is within its range.Having such a skill, the RFID are readily being implemented in the production sector as it can be used to track the status of a product through its assembly line.

The tags are fairly cheap with its prices ranging from $0.15-$100 depending upon the type of tag i.e passive, active or battery-assisted passive.The passive tag has no battery and thus it is cheaper and small in size, the active tag has an onboard battery source and the battery-assisted tag has a small battery which only gets activated in the presence of an RFID reader.The tags can be either read-only i.e having an assigned serial number impression that is used as a key into a respective database, or can be read/write, where the product-specific data can be written in by the system user.

The RFID is being implemented in various processes-

- Tracking of products and goods.

- Used in the tracking of people suffering from the Parkinson’s disease.

- Tracking of stray animals.

- Tracking of endangered animals to protect them from poaching and other illegal activities.

- Tracking baggage in and packed items in logistics.

- The collection of Toll and cashless payment.

All the above factors state that RFID is truly the next version to UPC and soon will take over the normal barcodes and QR codes.

Also read: Best cameras for YouTube videos